With Ympact Platform you can check easily, quickly and accurately your level of compliance with ZDHC standards for the chemicals used in the production processes of the fashion & luxury supply chains.

29 March 2023

If you are here, it is probably your company’s goal to promote best and innovative practices to advance the industry toward zero discharge of hazardous chemicals in order to protect your workers, customers, and the environment.

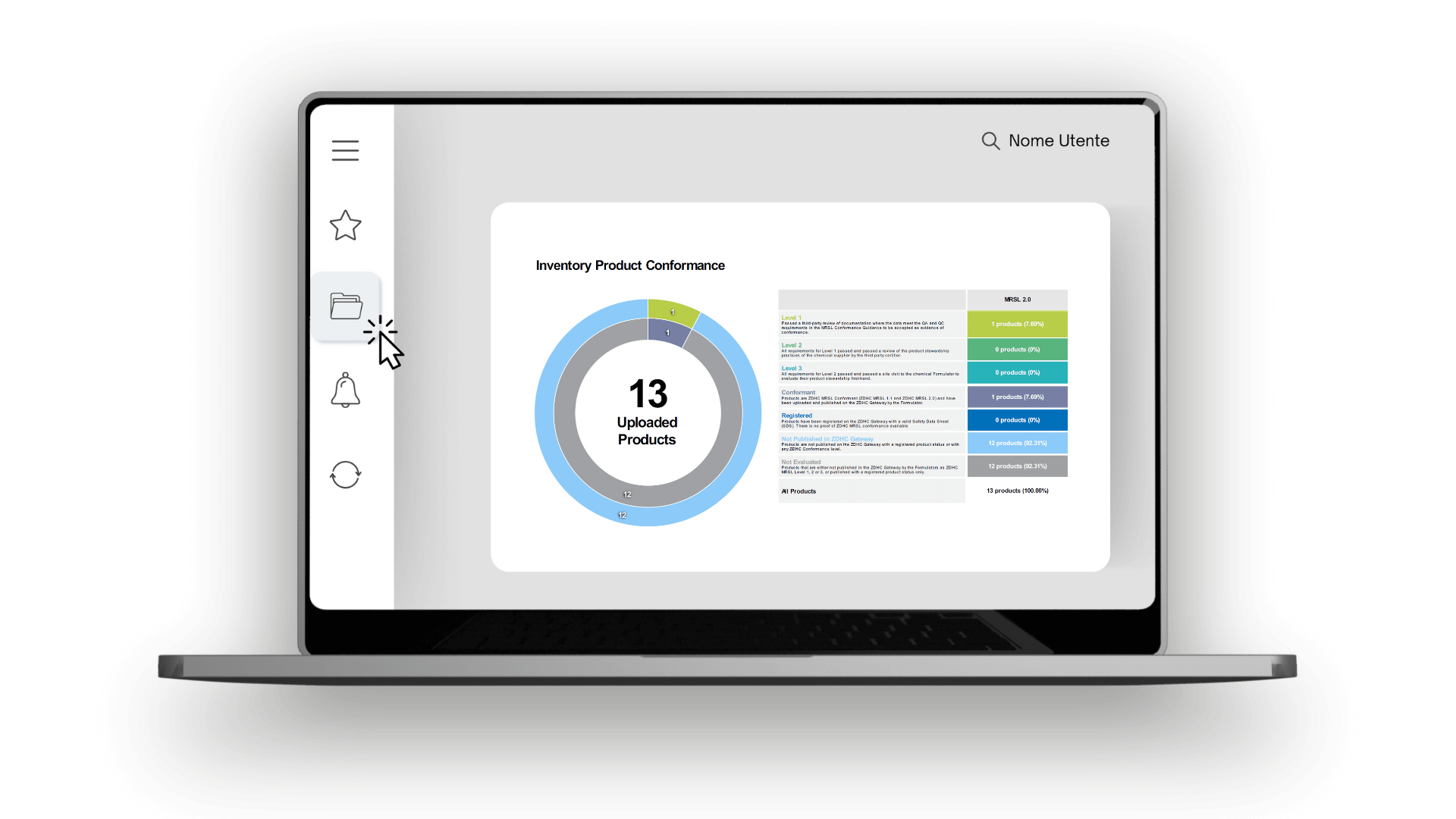

Ympact’s 4sCHEM+ platform aims to guide you in implementing the ZDHC sustainable chemical management system and Supplier to Zero program, and analyze chemical inventory performance through different reports.

4sCHEM+ is connected to the ZDHC Gateway and allows intuitively and easily to:

It will make it easier and faster to report inventory compliance with the ZDHC MRSL to the brand.

In this article, we will focus specifically on ZDHC Performance InCheck Reports, understand the guidelines provided by ZDHC and how you can follow them with the support of Ympact.

The ZDHC Roadmap to Zero has changed the way chemical management in the textile industry is approached, moving from product compliance to input management, i.e., the elimination of hazardous substances as early as the supplier input stage.

This approach promotes the use of clean inputs, which combined with the right process controls, generate safer and more sustainable products.

The ZDHC InCheck Solutions help suppliers demonstrate transparency and commitment to more sustainable chemical management. With these solutions, suppliers can purchase and use chemicals that minimize human health risks, improve worker safety and limit impacts on the environment.

The Performance InCheck Guidelines provide all the information suppliers and other stakeholders need to learn about the ZDHC InCheck Solutions and how to use the Performance InCheck Report.

We hope you find the information below useful! Remember that the ZDHC InCheck is an effective tool for demonstrating your commitment to sustainability and improving your chemical management.

In this first part, we explain how the ZDHC InCheck Solution helps textile suppliers adopt more sustainable chemistry. To better understand how it works, we need to introduce other important standards and solutions in ZDHC’s holistic approach.

1. Manufacturing Restricted Substances List

The first is the ZDHC Manufacturing Restricted Substances List or ZDHC MRSL, a list of chemicals that cannot be used in facilities.

The ZDHC MRSL Conformance Guidance and MRSL Conformance Pyramid explain how a supplier can ensure that its chemicals do not contain banned substances.

2. ZDHC Gateway – Chemical Module

In addition, the Gateway ZDHC – Chemical Module is a database that shows the compliance levels of chemical products with the ZDHC MRSL.

This tool allows suppliers to check their chemicals and find replacements with higher compliance levels.

3. Chemical Management System Framework

ZDHC’s Chemical Management System Framework, on the other hand, outlines the minimum requirements for a supplier’s management of chemicals.

Among the rest, the CMS Framework requires suppliers to maintain a list of all chemicals used, known as a Chemical Inventory List (CIL).

4. ZDHC InCheck

Finally, there is the ZDHC InCheck Solution, of which Ympact’s 4sCHEM+ platform is an enabler.

This tool provides an easy-to-understand overview of the ZDHC MRSL compliance levels of chemicals in a supplier’s chemical inventory.

By checking its chemicals against those recorded in the ZDHC Gateway – Chemical Module, a supplier can improve its overall performance and identify aspects that need improvement.

In short, the ZDHC InCheck Solution helps suppliers manage their chemical inventories toward more sustainable chemistry, which means safer chemicals for human health, the environment and workers.

The InCheck Solution is an important tool for suppliers seeking to manage chemicals safely.

It’s divided into two parts:

Both are designed to help suppliers improve compliance with ZDHC MRSLs. Let’s analyze the features and objectives of both.

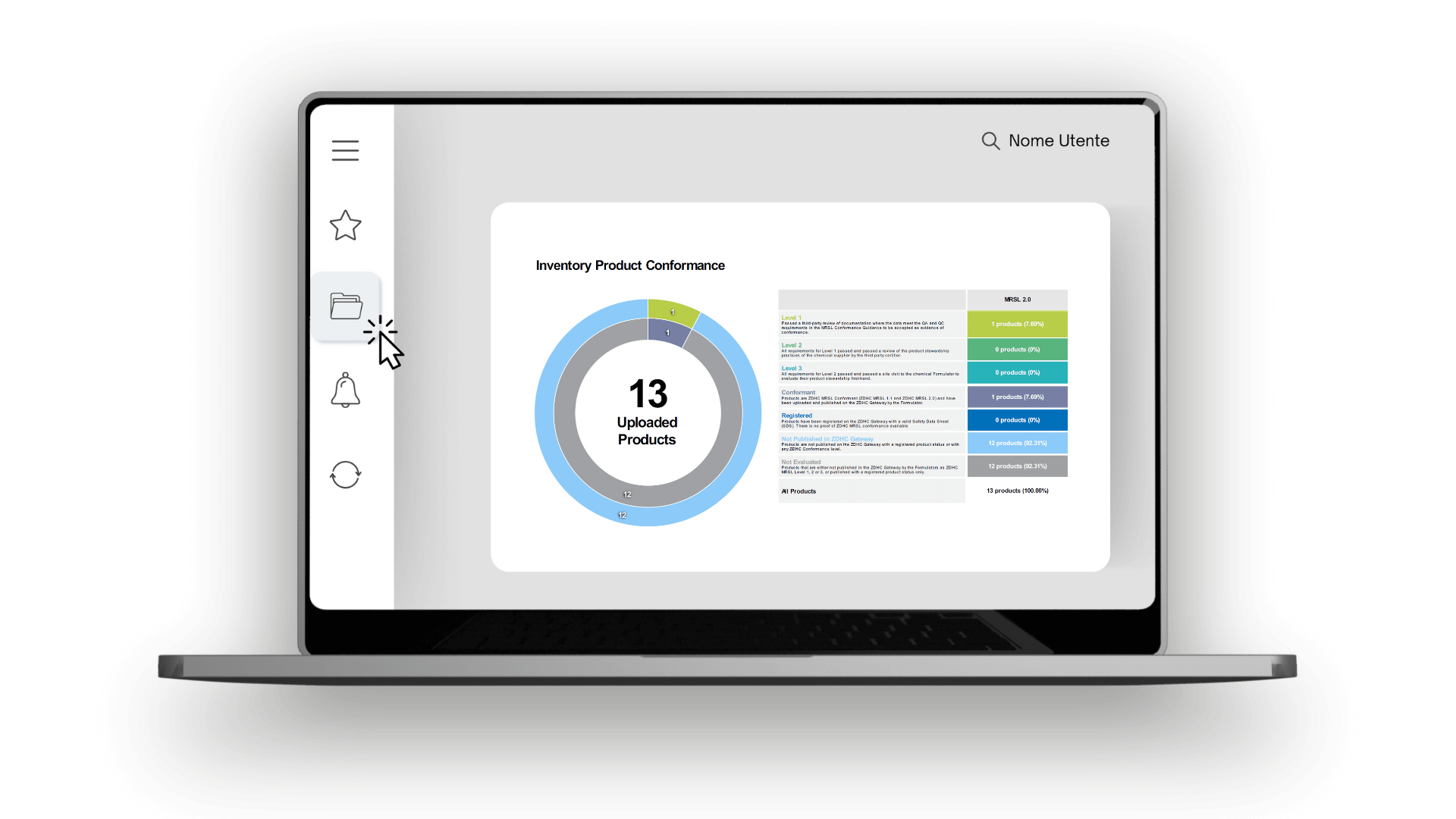

1. Performance InCheck Report

The Performance InCheck Report is based on a supplier’s chemical inventory data, but it is important to note that this data is not third-party verified.

The report is primarily used as an internal chemical monitoring tool to assess compliance with ZDHC MRSLs and motivate improvement.

The Performance InCheck Report contains information on:

It also provides a graphical representation of product compliance by number and weight.

It should be noted that the Performance InCheck Report is a self-assessment and should not be used to evaluate suppliers on their implementation of ZDHC MRSL in their inventory.

However, it can be used to demonstrate to stakeholders the MRSL ZDHC compliance levels of chemicals in the supplier’s inventory.

In summary, the Performance InCheck Report is a useful tool for suppliers seeking to safely manage chemicals by providing clear information on product compliance with ZDHC MRSLs and motivating continuous improvement.

2. Verified InCheck Report

To ensure proper management of incoming chemicals and ZDHC MRSL compliance for its stakeholders, suppliers can generate a Verified InCheck Report.

To do so, the supplier’s chemical inventory must be validated by a ZDHC-approved third- or second-party verifier through an on-site visit to the supplier.

The purpose of the verified InCheck report is to:

The verifier uploads the validated inventory to the ZDHC Gateway and the Verified InCheck Report is then used to communicate transparent and credible management of incoming chemical inventory for ZDHC MRSLs by a supplier.

What is the relationship between Performance InCheck and Verified InCheck Report?

Suppliers are advised to generate a Performance InCheck Report for a sufficient period before generating a Verified InCheck Report to continuously measure and improve the performance of their incoming chemical inventory against ZDHC MRSL compliance levels.

Only then can the Verified InCheck Report exercise be completed to communicate a credible status of the chemical inventory to its stakeholders, in line with ZDHC’s “trust but verify” principle.

Do you have doubts or want to learn more about InCheck Solution? Book a free demo call with us. We’re happy to help!

ZDHC needs to use the services of third-party service providers to assist providers in the process of generating the Performance InCheck Report.

Below, let’s take a step-by-step look together at how you can generate a Performance InCheck Report.

First, you need to register with the ZDHC gateway and create a vendor account.

After logging into their ZDHC Gateway account, the provider can access the Performance InCheck tab. Here he can find the link to the Implementation HUB.

On the Implementation HUB website, an overview of ZDHC-approved solution providers can be found and the preferred solution provider can be chosen.

After creating an account, the provider must activate the Performance InCheck option within the approved solution provider’s platform to proceed with InCheck generation.

It is also necessary to register on the ZDHC Gateway and the approved solution provider’s platform.

Having done these steps, the Provider will be able to:

It is important to remember that the Performance InCheck Report data is automatically linked to the ZDHC Gateway and can be found in the provider’s account, either in PDF or Excel format.

The 2 ways to track chemical inventory

To generate a credible Performance InCheck Report, a supplier can choose between two ways to track its chemical inventory: Delivery and Usage.

Delivery consists of the purchases made by the supplier in the previous month, and the purchased chemicals are assumed to have been used in the production facility for a certain period.

This type of inventory establishes the transparency of a supplier’s chemical inventory, and it is easier for the supplier to obtain records and start the continuous improvement process.

On the other hand, Usage is defined as the number of chemicals actually used or consumed during the reporting month.

An InCheck performance report should always reflect the previous month’s consumption levels and can be calculated using the formula: Quantity of usage = (quantity of chemical in stock at the beginning of the month + quantity of chemical delivered in the month) – quantity of chemical in stock at the end of the month.

Using both types of inventory can help a supplier continuously improve its chemical management and achieve desired levels of ZDHC MRSL compliance.

Delivery vs Usage: which is the best?

Compared with Delivery, the Usage-type inventory offers several advantages, including:

To ensure optimal inventory utilization, the amount of utilization should be automatically determined and recorded each month by the supplier’s warehouses or purchasing department.

This information should then be included in the Gateway Chemical Inventory, which can be easily uploaded to the Approved Solution Provider platform to generate the Performance InCheck.

In addition, it is possible to switch from the Delivery-type inventory to the Usage-type inventory once the systems required to calculate monthly consumption levels have been implemented.

In summary, Usage-type inventory is a powerful tool for ensuring sustainability in chemical usage, and suppliers can easily switch between inventory types to ensure maximum efficiency and traceability.

Rules for uploading chemical inventory

There are some important rules for uploading chemical inventory to the Approved Solution Provider platform.

Rule 1: Include all the correct and required information from the CIL.

Although the full CIL is required to meet the requirements of the ZDHC CMS Framework to ensure the safe management of chemicals in the facility, not all information is required for the generation of the Performance InCheck Report.

The following columns of the ZDHC CIL format must be filled in for inventory upload:

Rule 2: Include all required chemicals in the inventory upload.

To get a complete overview of the ZDHC MRSL compliance levels of a supplier’s chemical inventory, it is important to include all chemicals used in the facility.

However, chemicals not directly applied or used in production processes are not yet recorded on the ZDHC Gateway. Neither are basic chemicals. Therefore, it is currently difficult for a supplier to demonstrate compliance with the ZDHC MRSL for these products.

Since these chemicals are an important part of most suppliers’ chemical inventory, ZDHC is currently developing a strategy to include them in the scope of ZDHC Gateway.

Rule 3: Verify the correct name of the chemical and chemical formulator in the CIL

For maximum results, it is important to verify the correct name and spelling of chemicals in a supplier’s chemical inventory before uploading it to the Approved Solution Provider platform.

This can be done by checking the:

Only the name of the Formulator and not the name of the dealer/agent/distributor supplying the product for commercial transactions on behalf of the Formulator should be entered in the inventory format.

If the information on the SDS and the physical label do not match, the supplier must confirm the correct name of the chemical with the chemical supplier.

How often update the InCheck Performance Report

If you are a supplier who has already started generating Performance InCheck Reports, it is fundamental to know that you should do this once a month.

Once you have reached a high level of chemical entry into the ZDHC gateway for ZDHC MRSL compliance, the frequency of report generation may be different.

It could be on-demand if you want to align with brand requirements, or once or twice a year, following the Verified InCheck Report exercise and corrective actions completion needed to improve ZDHC MRSL Compliance of the verified inventory.

Remember: keeping your chemical inventory updated and in compliance is an essential step to ensure worker safety and the environment.

If you need more information or support, we are here to help!

After generating a Performance InCheck Report, the supplier may conclude that improvements are needed.

Two distinct scenarios may occur:

Scenario a: a Supplier may conclude that a substantial portion of the chemicals in its inventory is not registered in the ZDHC Gateway.

To ensure compliance with the MRSL ZDHC, the provider has several options available:

Scenario b: A Supplier may feel that it is not yet satisfied with the ZDHC MRSL compliance levels of the chemicals in its inventory.

To find alternatives to their chemical products with higher ZDHC MRSL compliance levels, the supplier can rely on the ZDHC Gateway – Chemical Model.

This tool allows searches by product name, formulator name, substrate type, or certification type.

After identifying chemical products with a high level of ZDHC MRSL compliance, the supplier can begin to prepare for the operation of the Verified InCheck Report.

It will enable it to verify the compliance of its chemical inventory and evaluate any corrective actions to be taken.

How to verify ZDHC MRSL compliance for unlisted chemicals

Even if a supplier makes every effort to ensure maximum ZDHC MRSL compliance in the Performance InCheck Report, it may be faced with chemicals that are not listed in the ZDHC Gateway or are not visible in the formulator profiles for various reasons.

To overcome this challenge, the supplier can take some general actions, such as:

We have come to the end of this article, and we hope that the information you found will be useful.

If you are interested in learning more about our solution and would like to know how it can help you with your business, book a free demo call with us.

fast. simple. accurate.

fast. simple. accurate.

1

TALK WITH US

Request a free consultation with one of our Ympact Specialists

2

SELF-ASSESS YOUR COMPANY

Register on the Ympact Platform and choose the 4s Chem assessment

3

get the incheck report

View your reports, consult them whenever you want and share them with interested parties

Ympact Srl

Società Benefit

HEADQUARTER

Piazza IV Novembre, 4

20124 – Milano (MI)

VAT NUMBER

IT12342390965

With Ympact Platform you can check easily, quickly and accurately your level of compliance with ZDHC standards for the chemicals used in the production processes of the fashion & luxury supply chains.