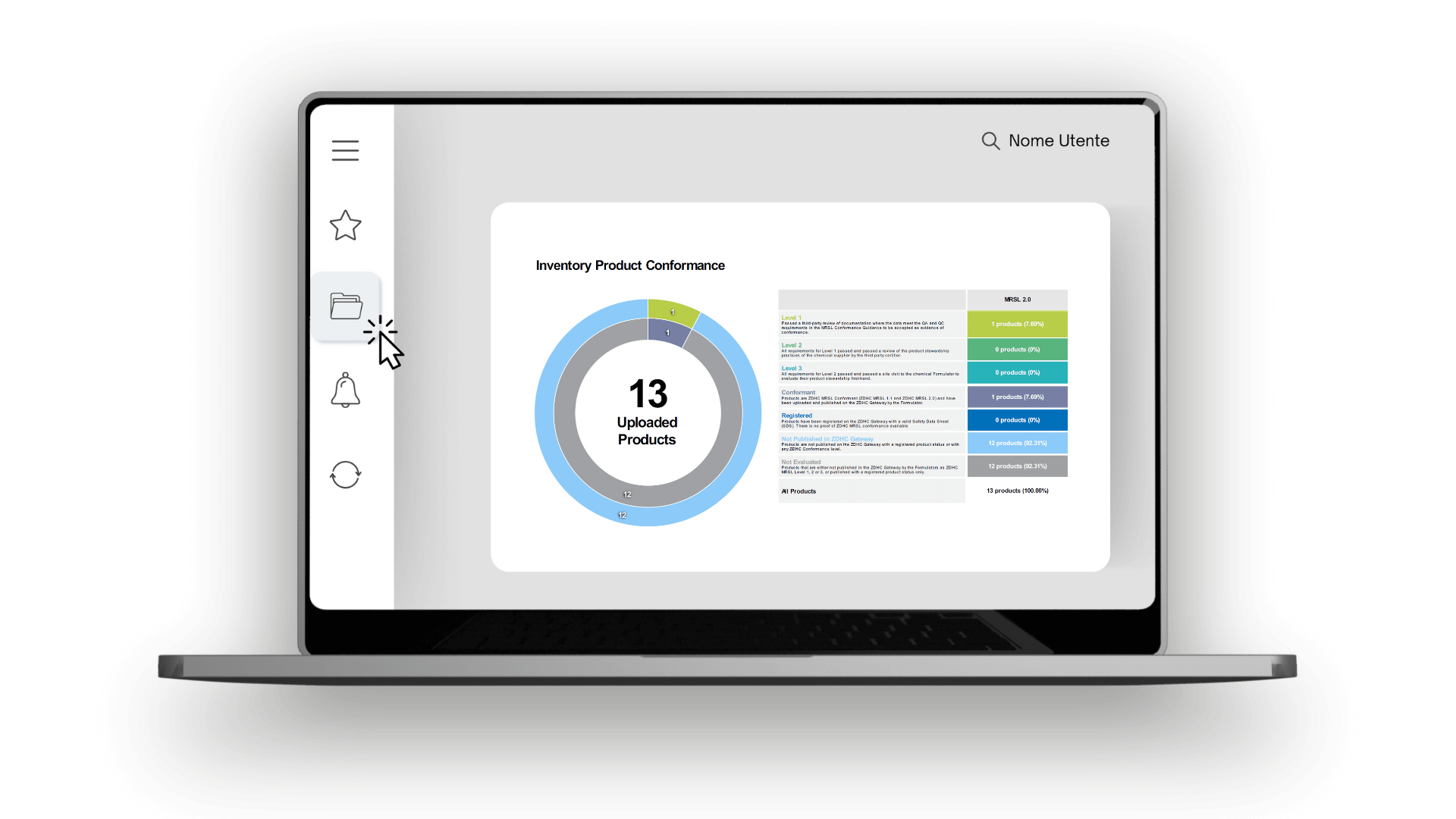

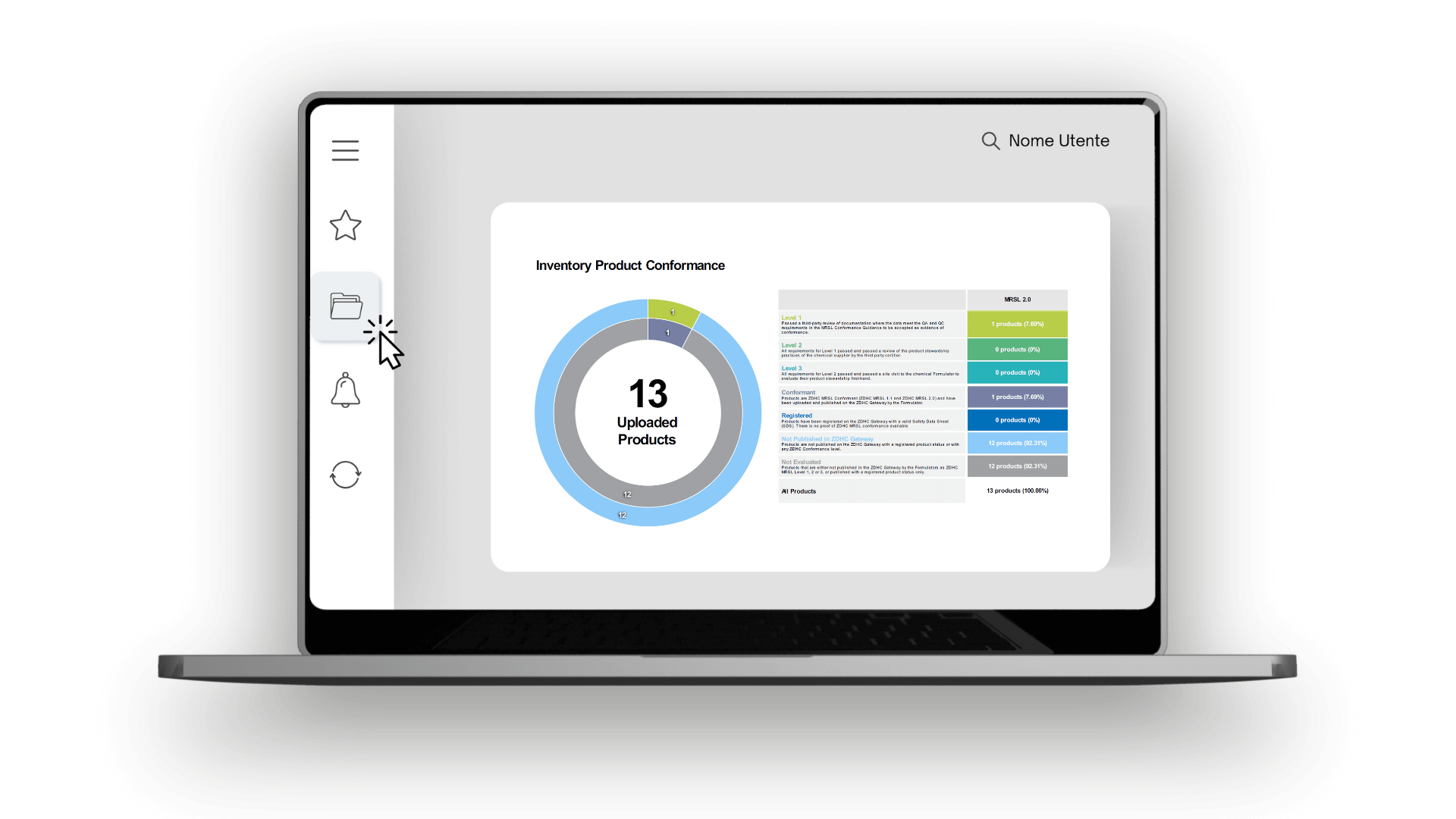

With Ympact Platform you can check easily, quickly and accurately your level of compliance with ZDHC standards for the chemicals used in the production processes of the fashion & luxury supply chains.

29 March 2023

Promoting best and innovative practices to advance the industry toward zero discharge of hazardous chemicals is probably one of the most urgent and priority challenges affecting brands and suppliers in the fashion industry.

Not only commitment, effort, innovation and speed are required, but it also becomes necessary to demonstrate efforts in this direction.

To implement a revolution, it is important to surround yourself with professionals and experts who share your values, vision and can simplify the process.

4sCHEM+, the Ympact’s platform, is by your side to guide you in implementing the ZDHC sustainable chemical management system and Supplier to Zero program, and analyze chemical inventory performance through different reports.

After seeing how to enable an InCheck Report by following the ZDHC’s guidelines with Ympact support, in this new article we will focus on ZDHC InCheck Solutions, that help you demonstrate the efforts you are making to improve the management of your chemical inventory and its compliance with the ZDHC MRSL.

As we reported in a previous article, ZDHC InCheck Solutions help suppliers demonstrate their efforts to improve their chemical inventory management toward sustainable chemistry and compliance with the ZDHC Manufacturing Restricted Substances List (ZDHC MRSL).

With these solutions, suppliers can purchase and use chemicals that minimize human health risks, improve worker safety and limit impacts on the environment.

In addition, ZDHC InCheck Solutions also enable suppliers to assess the compliance of their chemical inventory with the ZDHC MRSL and share the results with brands, without sharing details of the chemical inventory itself.

In short, a scalable and certified solution that adapts to your needs, allowing you to share only the primary information with the assurance of pursuing your goals while respecting others and zeroing in on risks.

In this first part, we explain how the ZDHC InCheck Solutions help textile suppliers adopt more sustainable chemistry. But to better understand how it works, we need to introduce other important standards and solutions in ZDHC’s holistic approach.

The first is the ZDHC Manufacturing Restricted Substances List or ZDHC MRSL, a list of chemicals that cannot be used in facilities.

The ZDHC MRSL Conformance Guidance and MRSL Conformance Pyramid explain how a supplier can ensure that its chemicals do not contain banned substances.

In addition, the Gateway ZDHC – Chemical Module is a database that shows the compliance levels of chemical products with the ZDHC MRSL.

This tool allows suppliers to check their chemicals and find replacements with higher compliance levels.

The Roadmap to Zero guides implementing an effective chemical management system (CMS), essential for worker safety and reducing the environmental impact on the planet and the community.

The goal of ZDHC, shared by Ympact, is to zero discharges of hazardous chemicals and continuously improve the process.

The ZDHC approach focuses on minimizing environmental impact and involves different stakeholders in the supply chain.

The ZDHC CMS Manual consists of two complementary parts:

In addition, the ZDHC CMS explains the importance for suppliers to maintain a chemical inventory list (CIL), which includes all chemicals used in processes and operations, checked against environmental impacts, such as compliance with the ZDHC MRSL.

ZDHC InCheck Solution is a great tool for suppliers who want to assess the ZDHC MRSL compliance level of chemicals in their chemical inventory.

Three different solutions complement each other and offer different levels of confidence to brand customers:

Let’s see together what they are and how they can support you in achieving your goals.

The Performance InCheck Report is a chemical inventory self-assessment that provides information on a supplier’s sustainable chemical management journey.

When the Performance InCheck logo is visible on the supplier’s ZDHC Gateway profile, it means that it has generated one or more Performance InCheck Reports.

The Performance InCheck Report is based on registered chemical inventory data and has to be used primarily as an internal monitoring tool for chemicals in the supplier’s chemical inventory.

It’s to be used to evaluate individual chemicals registered on ZDHC Gateway and certifications against the ZDHC MRSL.

We recommend that you conduct the self-assessment monthly to promote continuous improvement in the supplier’s chemical purchasing practices.

Although you can use the Performance InCheck Report to demonstrate the ZDHC MRSL compliance levels of your chemical inventory to interested stakeholders, it is essential to remember that this is a self-assessment.

To achieve a higher level of confidence, consider the Verified InCheck – Level 1 and 2 levels, which involve an on-site check by a ZDHC-approved verifier.

Let’s see what they are and how we can use them to our benefit.

Verified InCheck – Level 1 is a seal of approval for suppliers, signifying that they have passed the on-site audit performed by a ZDHC-authorized verifier.

This seal appears on the supplier’s ZDHC Gateway profile and indicates that the supplier’s claimed chemical inventory has been verified for completeness and accuracy based on the last three Performance InCheck reports.

The main objective of Verified InCheck – Level 1 is to verify the completeness and accuracy of the supplier’s chemical inventory against that published in the ZDHC Gateway – Chemical Module, thereby increasing confidence in the Performance InCheck reports generated by the supplier.

This verification should be used by suppliers to assess the robustness of their Performance InCheck process and results, ensuring that the chemicals in their chemical inventory meet ZDHC MRSL requirements.

In addition, the Verified InCheck – Level 1 adds a level of confidence to the Performance InCheck self-assessment because it has been verified through a spot check conducted by a ZDHC-approved verifier.

Finally, it is important to note that the Verified InCheck – Level 1 must be conducted annually to maintain the seal of approval on the ZDHC Gateway provider profile.

The Verified InCheck – Level 2 aims to achieve some important objectives.

First, it ensures the completeness and accuracy of a supplier’s chemical inventory against what is published in the ZDHC Gateway – Chemical Module.

It also provides a solid foundation for the supplier’s sustainable chemistry journey by providing transparent and credible verification of the entire chemical inventory for the past 12 months through an on-site audit.

This level of verification is an opportunity for suppliers to demonstrate to their partners their dedication to sustainable chemical management and implementation of the ZDHC MRSL, increasing confidence in their business relationships.

For this reason, at Ympact we recommend that Verified InCheck – Level 2 be conducted annually so that you can maintain high standards of transparency and sustainability.

Do you have doubts or want to learn more about ZDHC InCheck Solutions? Book a free demo call with us. We’re happy to help!

As we have seen in this article and the one about ZDHC’s guidelines, InCheck Solutions are key factors in the Roadmap to Zero Program implementation journey.

With the three different InCheck Solutions just seen together, we and ZDHC want to simplify your journey to more sustainable management of chemicals used in processes.

Constant efficiency in sustainable chemical management is a journey made in perpetual improvement, and we understand that suppliers have specific needs and varying degrees of chemical management system maturity.

Therefore, InCheck solutions are designed to fit your specific needs or the requirements of the brand you work for, in a flexible and scalable way along the way.

The first step is the Verified InCheck – Level 1 is based on the available Performance InCheck reports. Before you can request a Verified InCheck – Level 1, you will need to complete at least three Performance InCheck reports.

We recommend that you complete a Performance InCheck Report every month, but if your resources are limited, you may opt for a different timing.

Keep in mind that the maximum time interval between two Performance InCheck reports is two months for those who wish to request a Verified InCheck – Level 1.

On the other hand, The Verified InCheck – Level 2 represents a comprehensive audit of the chemicals stored and used during one year at the supplier’s facility.

This InCheck Solution allows you to conduct a thorough and accurate assessment or annual audit of your chemical inventory.

In the continuous improvement cycle, the Verified InCheck – Level 2 represents the end and starting point of the InCheck journey.

After the Verified InCheck – Level 2, you can repeat the process or adapt it based on your results.

For example: if you find many inconsistencies, you can increase the frequency of InCheck Solutions, while if the exercise provides a positive view of chemical management on site, you can repeat the process annually to monitor progress.

We have come to the end of this article, and we hope that the information you found will be useful.

If you are interested in learning more about our solution and would like to know how it can help you with your business, book a free demo call with us.

fast. simple. accurate.

fast. simple. accurate.

1

TALK WITH US

Request a free consultation with one of our Ympact Specialists

2

SELF-ASSESS YOUR COMPANY

Register on the Ympact Platform and choose the 4s Chem assessment

3

get the incheck report

View your reports, consult them whenever you want and share them with interested parties

Ympact Srl

Società Benefit

HEADQUARTER

Piazza IV Novembre, 4

20124 – Milano (MI)

VAT NUMBER

IT12342390965

With Ympact Platform you can check easily, quickly and accurately your level of compliance with ZDHC standards for the chemicals used in the production processes of the fashion & luxury supply chains.